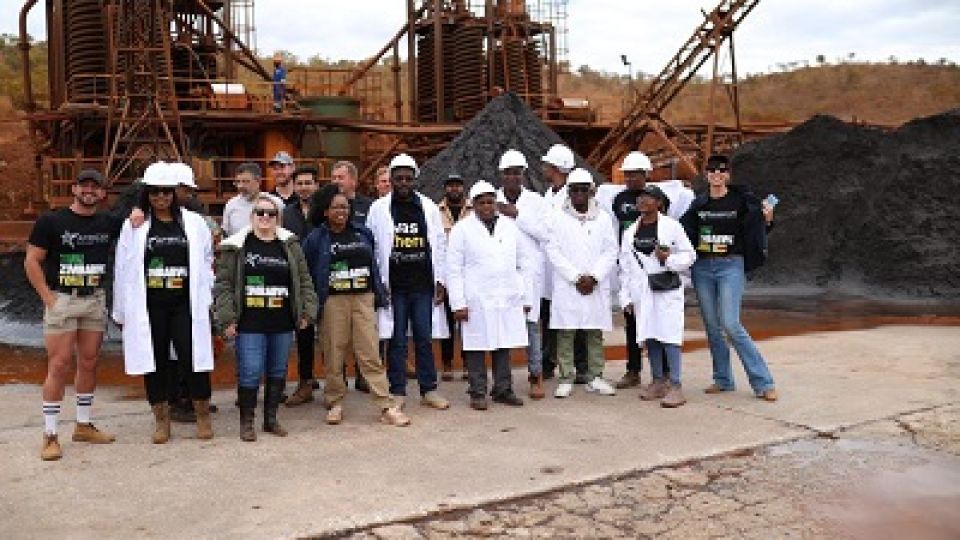

from SAVIOUS KWINIKA recently in Harare, Zimbabwe

Zimbabwe Bureau

JOHANNESBURG, (CAJ News) – AN investment of R800 million (US$42 million) on a mineral beneficiation plant by African Chrome Fields (ACF) has placed the company and Zimbabwe at the forefront of mining technology.

The plant utilises a world-first aluminothermic process.

South African-based Chrome Fields has an investment of $250 million (R4,7 billion) at present in Zimbabwe.

The abovementioned technology is the culmination of several years of research and testing, and was specifically developed in response to a lack of available power and infrastructure in the area, stated Zunaid Moti, Chairman and Country Representative of ACF.

He noted the Zimbabwean government has placed increasing focus over the years on beneficiating its natural resources and minerals as opposed to exporting raw material, with the aim of promoting inclusive, sustainable economic growth.

“In line with this thinking, we took the decision to build a plant to beneficiate our chrome within the country,” Moti said.

“So, over the past few years, we have invested more than R1,2 billion to develop completely new technology that is not dependent on electricity.”

Unlike traditional power-hungry and carbon-intensive furnaces, the aluminothermic plant draws on a proprietary chemical mix to produce the heat needed to convert raw chrome ore into ferrochrome, a specialized ferroalloy used in stainless steel manufacturing.

This proprietary mix ensures that the ferrochrome produced is ultra-low carbon, high-grade ferrochrome featuring between 62 percent and 65 percent chromium and just 0,2 percent carbon – a quality that is unmatched by most international counterparts.

In addition to its aluminothermic technology, the company’s boasts extensive alluvial mining operations in the area, only drawing on the upper layers of soil between one and three metres deep to extract chrome.

It currently has seven wash plants, the latest of which is a double plant that has increased its chrome production to 550 tons of chrome per day, or 20 000 tons per month.

Once production at plant six commences, production will increase to 30 000 tons per month. Plant six is scheduled to commence operations in the next 90 days.

The company has invested some $250 million into expanding its mining operations since 2014.

Its staff component has grown from less than 40 individuals to currently over 600 employees.

The life of the mine is expected to endure for at least 20 years, if not 30 or 40 years.

– CAJ News